Stock code

300440

300440

028-8283 9999

中文

中文

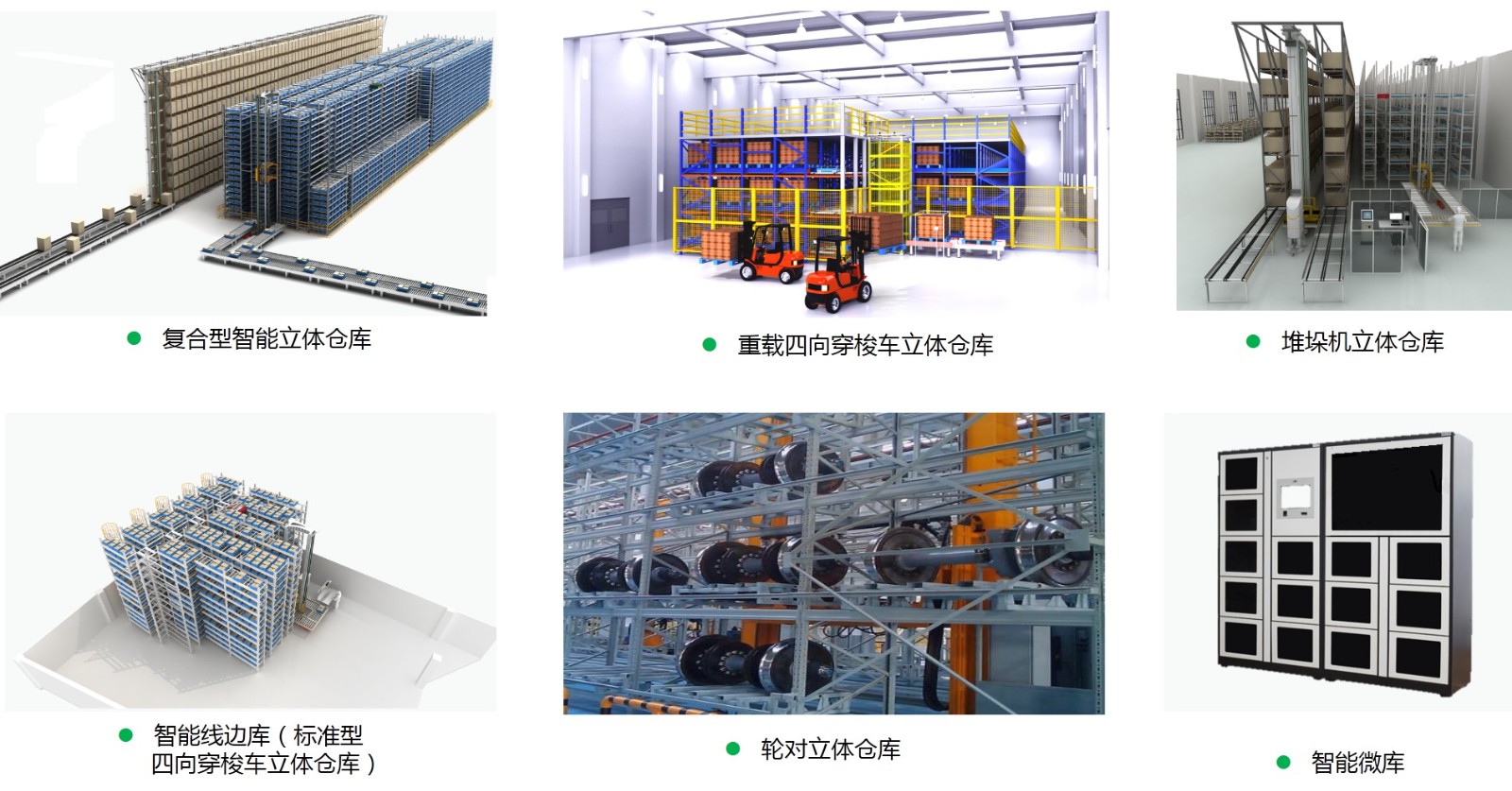

Process equipment integration - intelligent storage products are production-oriented, maintenance process-oriented, integrated with "people, vehicles, things" multi-dimensional products, supported by the Internet of Things technology, information technology, special collection equipment, in all aspects of logistics turnover, the use of sensing, collection and analysis technology, to achieve the goal of timely response, dynamic scheduling, a high degree of coordination of modern storage and logistics capabilities. With the orientation of "professionals doing professional work" and the goal of "maximizing the effectiveness" of work types and work stations, we provide a complete set of solutions for the material security of the machine service (vehicle) overhaul business. From intelligent warehousing to human-machine picking to "point-to-point" precision delivery, the product has formed a closed-loop logistics process around the overhaul business. By enhancing the application function of warehousing, we decouple and separate the overhaul and parts distribution business to achieve the purpose of reducing labor, enhancing productivity and improving enterprise productivity, and helping the enterprise transformation of the road bureau. Based on the integration of data flow and business flow, and can deeply integrate the company's maintenance, preparation and other business systems, fit the maintenance process, "lean production, lean logistics" concept as a guide, to achieve the automation, visualization, control and intelligence of the maintenance business field logistics, thus reducing labor intensity, improve resource utilization and production efficiency, and lay a solid foundation for the construction of intelligent machinery, vehicle section.

Email:gtbg@yunda-tec.com